M390 vs. N690 steel arguments frequently spark heated debates among knife lovers and metallurgy experts. Both are admired for their remarkable performances, but what distinguishes them? In this detailed article, we’ll look at the differences between M390 and N690 steel, their uses, and commonly asked questions to help you decide which steel is best for your knives.

M390 vs N690

Understanding M-390 Steel

M390 is a high-performance powder metallurgy stainless steel known for its excellent corrosion resistance, edge retention, and toughness. Bohler-Uddeholm created it as part of a series of premium steels suited for demanding applications with critical performance.

Properties of M390:

Edge Retention:

One of the most notable qualities of the M390 is its excellent edge retention. Because of its high carbon concentration and small grain structure, the M390 retains an edge very well, making it a favorite among knife manufacturers and consumers.

Corrosion Resistance:

M390 is highly corrosion resistant, making it ideal for use in areas with widespread moisture and severe conditions.

Toughness:

Despite its hardness, M390 retains a substantial amount of toughness, allowing knives manufactured from this steel to resist vigorous use without chipping or breaking.

M390 steel is commonly used in high-end folding, fixed-blade knives, and bespoke designs. Its edge retention, corrosion resistance, and hardness make it an excellent choice for outdoor lovers, professional cooks, and collectors looking for high-performance blades.

N690 Steel: Overview

Bohler-Uddeholm’s N690 stainless steel is a popular choice for knife makers. It has a well-balanced mix of edge retention, corrosion resistance, and sharpenability, making it a favorite option among knife producers and users worldwide.

Properties of N690:

Edge Retention:

While not as well known for edge retention as M390, N690 performs admirably. It keeps a sharp edge even after lengthy use, needing less sharpening than many other stainless steels.

Corrosion Resistance:

N690, like M390, has high corrosion resistance, making it appropriate for use in maritime situations and other settings where moisture is problematic.

One of the most notable qualities of the N690 is its ease of sharpening. With the correct equipment and procedures, it can be swiftly polished to a razor-sharp edge, making it desirable to users who wish to keep their knives in good condition.

Applications for N690:

N690 steel is widely used in various knives, including hunting knives, tactical blades, and daily carry (EDC) folders. Its balanced performance makes it a flexible choice for consumers looking for a dependable blade that can thrive in various jobs and settings.

Key Differences Between M390 and N690

Chemical composition

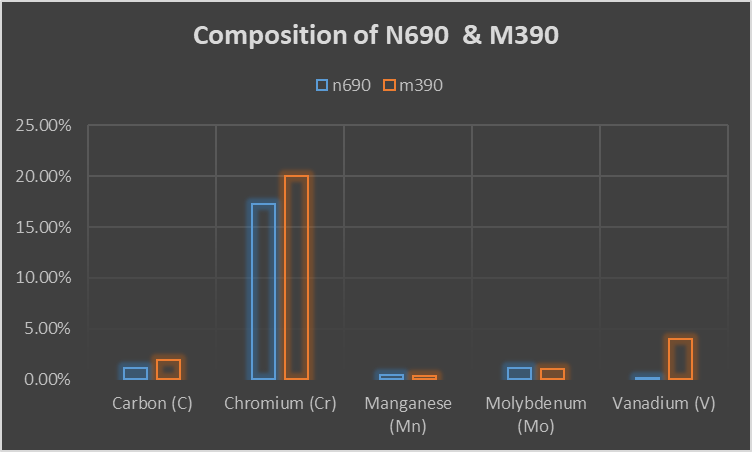

M390 is a high-carbon stainless steel that includes chromium, molybdenum, vanadium, and tungsten. Its exact composition leads to superior edge retention and corrosion resistance.

N690 includes chromium, molybdenum, and vanadium, although in somewhat different amounts than M390. It often has a reduced carbon concentration, affecting edge retention and sharpenability.

Edge Retention vs Sharpenability

M390

Known for its exceptional edge retention, M390 performs in circumstances where long-term sharpness is crucial. However, its extreme hardness may need additional work and specialist equipment to sharpen adequately.

N690

While it may not have the same edge retention as M390, it strikes a nice compromise between edge retention and ease of sharpening. It may require more regular touch-ups, but it is often more forgiving in terms of care.

Toughness and Impact Resistance

M390

Despite its high hardness, M390 retains a substantial degree of toughness, allowing blades manufactured from this steel to resist rigorous tasks without chipping or breaking.

N690:

N690 has good toughness, although it may be weaker than M390 under harsh situations. Nonetheless, it is durable enough for most daily jobs and outdoor activities.

Frequently Asked Questions.

Which steel is better: M390 or N690?

The answer depends on your priorities. If you value edge retention and corrosion resistance above everything else, the M390 is a better option. However, if you value ease of sharpening and a decent mix of performance features, the N690 may be a better choice.

Are there major pricing variations between knives produced from M390 and N690?

Knives made in M390 are often more expensive due to the steel’s costly manufacturing method and premium qualities. N690 knives are often less expensive while yet provide excellent performance.

Can I sharpen N690 and M390 steel at home?

While both steels may be sharpened at home with the proper tools and procedures, M390 may need more work and specialist pointing equipment due to its greater hardness. Most users, however, find it easier to sharpen the N690.

Conclusion

The choice between M390 and N690 is subjective and depends on personal tastes and requirements. Whether you value edge retention, ease of sharpening, or overall performance, both m390 vs n690 steels have excellent features that appeal to a wide spectrum of knife aficionados. Understanding the differences between each steel and evaluating your intended use will allow you to decide and choose the best steel for your next knife purchase or project.