Damascus steel is a type of steel that has been used for centuries to create swords, knives, and other metal pieces. It is known for its unique pattern and strength, but there is still some debate about whether or not it is brittle. Some people believe that Damascus steel is too soft or unreliable for practical applications, while others argue that it is one of the strongest types of steel available.

Despite the ongoing debate, there is evidence to suggest that Damascus steel can be brittle under certain conditions. The layered construction of Damascus steel can make it more prone to cracking or breaking if subjected to excessive force or impact. Additionally, some types of Damascus steel may be more brittle than others, depending on the specific materials and techniques used in their production. However, it is important to note that not all Damascus steel is inherently brittle, and many high-quality pieces are able to withstand significant wear and tear without issue.

Quick Answer: Is Damascus Steel Brittle?

Damascus steel is a type of steel that is known for its unique pattern and strength. However, there is a common misconception that Damascus steel is brittle and prone to breaking.

In reality, the answer to whether Damascus steel is brittle or not is not straightforward. It depends on the specific composition and quality of the steel.

Damascus steel is a type of layered steel made by forge welding two or more different types of steel together.

The layers are then repeatedly folded and forged to create the characteristic pattern. The resulting steel can have varying degrees of toughness and hardness depending on the specific combination of metals used and the heat treatment applied.

Some Damascus steels can be brittle due to a high carbon content or improper heat treatment. However, properly made Damascus steel can be tough and durable, with a combination of hardness and flexibility that makes it ideal for use in knives and other tools.

It is important to note that not all Damascus steel is created equal. The quality of the steel can vary greatly depending on the skill of the maker, the materials used, and the production process.

In summary, the answer to whether Damascus steel is brittle or not is not a simple yes or no. It depends on the specific composition and quality of the steel. While some Damascus steels can be brittle, properly made Damascus steel can be tough and durable.

What is Damascus Steel?

Damascus steel is a type of steel that has been used for centuries to make swords, knives, and other cutting tools. It is known for its unique pattern, which is created by the way the steel is forged and folded. Damascus steel is often associated with the Middle East, where it was first produced, but it was also made in other parts of the world.

The exact composition of Damascus steel is not known, but it is believed to be an alloy of iron and carbon, with other elements added to give it its unique properties. One theory is that Damascus steel was made from a type of steel called wootz, which was produced in India and Sri Lanka. Wootz steel was known for its high carbon content and was highly prized for its strength and durability.

To make Damascus steel, the steel is first heated to a high temperature and then folded over and over again. This process helps to distribute the carbon and other elements evenly throughout the steel, creating a strong, durable alloy. The folding process also creates the distinctive pattern that is characteristic of Damascus steel.

Despite its reputation for strength and durability, some people believe that Damascus steel is brittle and prone to breaking. However, this is not necessarily true. While it is true that some Damascus steel blades have been known to break, this is usually due to poor craftsmanship or improper use. When made properly, Damascus steel is a strong and durable material that can withstand a lot of wear and tear.

In conclusion, Damascus steel is a unique and beautiful material that has been used for centuries to make some of the world’s finest cutting tools. While its exact composition is not known, it is believed to be an alloy of iron and carbon, with other elements added to give it its unique properties. When made properly, Damascus steel is a strong and durable material that can last for generations.

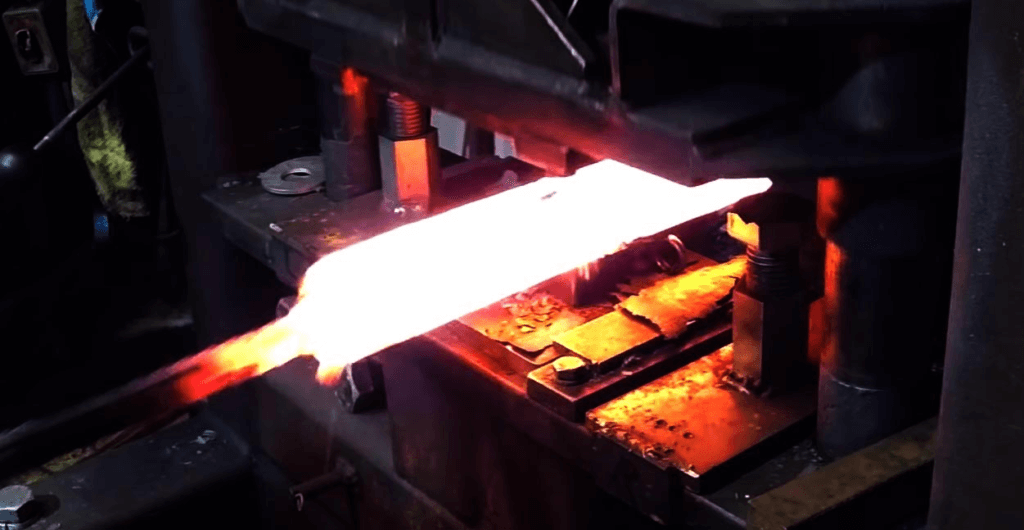

Damascus Steel Forging Process

Damascus steel is a type of steel that is known for its unique pattern and strength. The forging process of Damascus steel is a complex one that involves several steps.

The process of making Damascus steel involves welding together several layers of steel to create a billet. The billet is then heated to a high temperature and hammered to create a flat sheet. This sheet is then folded over itself and hammered again.

This process is repeated several times, with the number of folds depending on the desired pattern and strength of the final product.

During the forging process, the steel is heated to a high temperature to make it malleable. The temperature at which the steel is heated can vary depending on the type of steel being used and the desired properties of the final product.

After the steel has been forged and shaped, it is heat treated to harden it. The heat treatment process involves heating the steel to a high temperature and then rapidly cooling it. This process makes the steel harder and more durable.

Annealing is another important step in the forging process. Annealing involves heating the steel to a high temperature and then slowly cooling it. This process helps to relieve any stress in the steel and makes it more malleable.

Tempering is also an important step in the forging process. Tempering involves heating the steel to a specific temperature and then cooling it slowly. This process helps to reduce the hardness of the steel and make it more ductile.

Laminating is the process of layering different types of steel together to create a billet. This process is used to create the unique pattern that is characteristic of Damascus steel.

Metallurgy is an important aspect of the forging process. The type of steel used, the temperature at which it is heated, and the cooling rate all play a role in the final properties of the steel.

Overall, the forging process of Damascus steel is a complex one that involves several steps. The process requires skill and knowledge to create a high-quality product.

The Science Behind Damascus Steel

Damascus steel is a type of steel that has been used for centuries to make swords, knives, and other cutting tools. It is known for its distinctive patterns and its ability to hold a sharp edge. But is Damascus steel brittle?

The answer is no, Damascus steel is not inherently brittle. In fact, it is known for its toughness and durability. The reason for this is the way it is made.

Damascus steel is made by layering two or more different types of steel together and then forging them into a single piece. The layers are then etched with acid to reveal the distinctive pattern. The process of layering and forging the steel creates a material that is both hard and flexible, making it ideal for use in cutting tools.

The quality of Damascus steel depends on the quality of the materials used to make it. The carbon content of the steel is an important factor in determining its hardness and toughness. High-carbon steel is harder but more brittle, while low-carbon steel is softer but more ductile. The best Damascus steel is made from a combination of high-carbon and low-carbon steels, creating a material that is both hard and tough.

Recent advances in technology and nanotechnology have allowed for the creation of superplastic alloys that are even stronger and more durable than traditional Damascus steel. These alloys are made by mixing different metals together at the atomic level, creating a material that is both hard and flexible.

In conclusion, Damascus steel is not inherently brittle. It is a durable and tough material that is ideal for use in cutting tools. The quality of Damascus steel depends on the quality of the materials used to make it, particularly the carbon content of the steel. Recent advances in technology and nanotechnology have allowed for the creation of even stronger and more durable superplastic alloys.

Durability and Performance

Damascus steel is known for its unique layered pattern and has been used for centuries to create high-quality knives, swords, and other cutting tools. However, there is a debate about whether Damascus steel is brittle or not.

When it comes to durability, Damascus steel is generally considered to be a strong and long-lasting material. The layered construction of Damascus steel allows it to withstand wear and tear, making it an ideal choice for cutting tools that are used frequently. Moreover, Damascus steel is known for its ability to hold a sharp edge, which means that it requires less maintenance than other types of steel.

In terms of performance, Damascus steel is often praised for its flexibility and ability to absorb shock. The layered structure of the steel allows it to flex without breaking, which is an important quality for knives and swords that are used for cutting and chopping. Additionally, the unique pattern of the steel can help to reduce friction when cutting, which can make the cutting process smoother and more efficient.

However, there are some concerns about the brittleness of Damascus steel. Due to the layered construction, Damascus steel can be more prone to cracking or breaking if subjected to excessive force or impact. This is especially true for poorly made Damascus steel that is not properly heat-treated or forged.

To ensure the durability and performance of Damascus steel, it is important to use high-quality materials from a reputable forge. Proper heat treatment and forging techniques can help to improve the strength and flexibility of the steel, while reducing the risk of brittleness and cracking.

Overall, while there are some concerns about the brittleness of Damascus steel, it is generally considered to be a durable and high-performing material for cutting tools. With proper care and maintenance, Damascus steel can last for many years and provide excellent cutting performance.

Distinctive Patterns and Aesthetics

Damascus steel is renowned for its distinctive patterns and aesthetics, which make it a popular choice for knives, swords, and other decorative items. The patterns are created by folding and welding together layers of different types of steel, resulting in a unique banded, mottled, or layered appearance. The layers are then etched with acid to bring out the contrast between the different metals, creating a beautiful wavy pattern that is highly sought after.

The sharp edge and keen edge of Damascus steel are also highly valued by knife enthusiasts. The layers of steel create a micro-serrated edge, which helps to grip and cut through materials with ease. This unique feature also helps to maintain the sharpness of the blade for longer periods of time, making it a popular choice for chefs and hunters alike.

The lore and literature surrounding Damascus steel also add to its aesthetic appeal. The steel is said to have been first created in ancient Syria, and was highly prized for its strength and sharpness. The swords made from Damascus steel were said to be able to cut through a silk scarf in mid-air, and were highly sought after by warriors and nobles alike.

Overall, the distinctive patterns and aesthetics of Damascus steel make it a highly desirable material for knives, swords, and other decorative items. The sharpness and keen edge of the blade, combined with its unique appearance, make it a popular choice for collectors and enthusiasts alike.

Are Damascus Steel Knives and Swords Brittle?

Damascus steel is a type of steel that has been used for centuries to create high-quality knives and swords. There is a lot of debate about whether or not Damascus steel is brittle, and this is a topic that has been discussed among experts for many years.

One of the main reasons why people believe that Damascus steel is brittle is because it is made up of multiple layers of steel that are welded together. This can create weak points in the steel, which can make it more susceptible to breaking or cracking. However, this is not always the case.

In fact, many experts believe that Damascus steel is actually less brittle than other types of steel. This is because the manufacturing process used to create Damascus steel involves folding and welding the steel multiple times, which helps to remove impurities and create a more uniform structure. This can make the steel stronger and more durable, which can help to prevent cracking or breaking.

Another factor that can affect the brittleness of Damascus steel is the quality of the steel used in the manufacturing process. High-quality Damascus steel is typically made from high-carbon steel, which is known for its strength and durability. However, lower-quality Damascus steel may be made from cast iron or other materials, which can make it more brittle and prone to breaking.

Overall, while there is some debate about whether or not Damascus steel is brittle, many experts believe that it is actually less brittle than other types of steel. This is due to the unique manufacturing process used to create Damascus steel, as well as the high-quality steel that is typically used in the process. So, if you are looking for a high-quality knife or sword that is both strong and durable, Damascus steel may be a great option to consider.

The History and Lore of Damascus Steel

Damascus steel is a type of steel that has been known for centuries for its unique pattern and strength. The steel was originally produced in the Middle East, specifically in Syria and India, and was used to make swords, knives, and other weapons. The steel was also used to make armor, as it was known for its ability to withstand blows without breaking.

One of the most famous users of Damascus steel was Saladin, the Muslim warrior who fought against the Crusaders in the 12th century. Saladin was known for his skill with a sword, and he reportedly carried a Damascus steel sword that was so sharp it could cut through a silk scarf falling on it.

The process of making Damascus steel was a closely guarded secret, and the exact method is still not known today. It is believed that the steel was made by combining different types of iron and steel, and then heating and folding the metal repeatedly to create the distinctive pattern.

In Japan, a similar type of steel was produced called “Tamahagane,” which was used to make samurai swords. Like Damascus steel, Tamahagane was made by combining different types of iron and steel, and then folding and heating the metal repeatedly to create a strong, flexible blade.

In recent years, Damascus steel has gained renewed interest due to its appearance in popular culture, particularly in the book series “A Song of Ice and Fire” by George R.R. Martin and the television show “Game of Thrones.” In the series, a type of steel called “Valyrian steel” is said to be made using a similar process to Damascus steel, and is known for its strength and ability to kill supernatural creatures. While Valyrian steel is fictional, it is believed to be inspired by the real-life Damascus steel.

Modern Damascus Steel

Modern Damascus steel is a type of steel that is made by combining and layering different types of steel. It is a high-quality material that is used to make knives, swords, and other tools. The manufacturing process of modern Damascus steel involves several steps, including forging, welding, and hammering. The craftsmen who make modern Damascus steel are highly skilled and have years of experience in working with steel.

One of the main advantages of modern Damascus steel is that it is made from high-quality materials. The steel used to make modern Damascus steel is often made from high-carbon steel, which is known for its strength and durability. This makes modern Damascus steel a practical choice for those who need a tool that can withstand heavy use.

Another advantage of modern Damascus steel is that it is expensive. The manufacturing process of modern Damascus steel is time-consuming and requires a lot of skill and expertise. As a result, the cost of modern Damascus steel is often higher than that of other types of steel.

Despite its high cost, modern Damascus steel is still widely used by craftsmen and artisans. This is because it is a practical material that is also aesthetically pleasing. The unique patterns and designs that are created by the layering of different types of steel make modern Damascus steel a popular choice for those who want a tool that is both functional and beautiful.

In conclusion, modern Damascus steel is a high-quality material that is used to make knives, swords, and other tools. It is made from high-quality materials and is manufactured using a time-consuming and expensive process. Despite its high cost, modern Damascus steel is still widely used by craftsmen and artisans because of its practicality and aesthetic appeal.